BSDF 3-Stage Hammer Mill

BSDF 3-Stage Hammer Mill unit includes:

1) crusher part

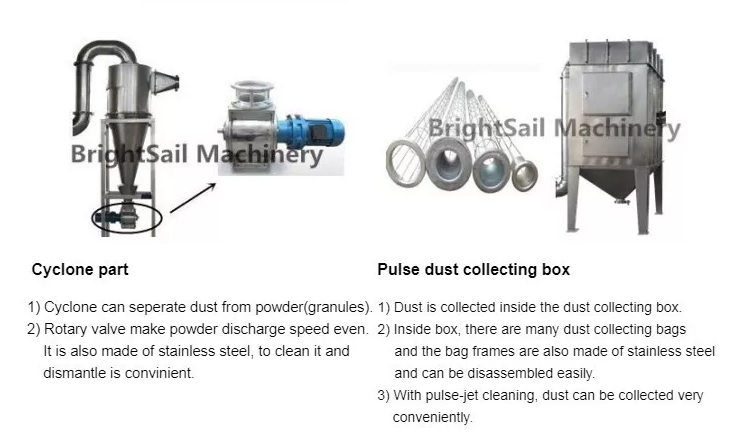

2) cyclone (discharge system)

3) pulse dust collecting system

4) blower

5) electrical control box

Material is sent to mill chamber to be crushed, by force of blower, powder will go to cyclone and be discharged, the ultra-fine

powder will be seperated to dust collecting box.

The production process is dust-free and continuous. BSDF advanced hammer grinding set is suitable for grinding spices, like ginger, garlic, chilli...etc.

Technical Data of BSDF 3-Stage Hammer Mill

|

Model |

BSDF-350 |

BSDF-450 |

BSDF-550 |

BSDF-750 |

|

Rotor speed (rpm) |

3500-4500 |

3300-4200 |

2900-3600 |

2100-2700 |

|

Grind motor (kw) |

22 |

37 |

45 |

75 |

|

Discharge motor (kw) |

0.75 |

0.75 |

1.1 |

1.5 |

|

Blower (kw) |

7.5 |

11 |

15 |

18.5 |

|

Fineness (mesh) |

20-120 |

20-120 |

20-120 |

20-120 |

|

Capacity (kg/hr) |

100-200 |

300-500 |

600-800 |

800-1300 |

Crusher part:

It combines coarse crushing area, middle fine milling area and super fine milling area together. Each group has one unit of knives and one liner.

Material is fed into the mill chamber, pass through the high speed rotation caused by the three groups of knives one by one.

Material is crushed three times in one mill chamber, then become fine powder. Between middle fine crush knife group and fine mill

knife group, there is a device designed for preventing coarse granule going to fine milling area, so powder fineness is assured.

The rotor speed is controlled by inverter, different particle size is achieved by adjusting rotation speed.

Advantages:

1) No need screen or sieve in mill chamber, change powder particle size by changing speed through inverter;

2) Because it has no screen in mill chamber, it can make finer powder than common hammer grinder machines.

3) The mill part combines coarse crusher, middle fine mill and fine mill together, which means it can makes fine powder directly

from big raw material, very effective. Then, no need to crush big material firstly.

4) It can save more power, its capacity is much bigger than other traditional hammer mills.

Jiangyin Brightsail Machinery focuses on one-stop overall powder process solutions.

The solution covers from cleaning machine,cutting machine,dryer, roaster, crusher, grinding mill,mixer,to filling and packing

machines...etc.

Till 2023 year, we have exported our machines to more than 84 countries around the world and have received a lot positive

feed-backs from our customers.

Besides, we also provide other solutions for food and chemical powder processing.

Q: What will be the payment way?

A: Usually, we accept T/T, and sometimes, we can also accept LC, and credit card.

Q: Can the Hammer Mill size be customized?

A: Yes, maybe we can. You shall tell us the room size of your factory, so we can adjust the design to fit in your space, we can try it.

Q: Can the machine’s voltage be customized?

A: Yes, sure. Like 220V,400V, 480V, 600Hz....we can do it.

This is our BSDF-350 hammer mill for dried onion grinding

the fineness of the powder reaches more than 60 mesh

In the video, it is our BSDF advacned 3-stage hammer mill

crusher cinnamon it can also be used to crush herbs